Lean Manufacturing with 4D Printing

Several leading additive manufacturing research facilities, including MIT’s Self-Assembly Lab, 3D printing manufacturer Stratasys, and 3D software company Autodesk, are taking 3D manufacturing to the next level by creating objects that can change their shape over time in response to various external stimuli.The new process, called 4D printing, relies mostly on shape-memory polymers, which can form complex structures when exposed to heat, moisture, light, or, for example, kinetic energy. While still in it’s infancy, 4D printing has already been demonstrated by several universities.

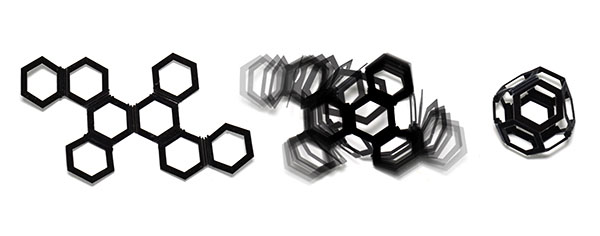

Zhen Ding at the Singapore University of Technology and Design and his colleagues are using standard commercial 3D printers to rapidly print rigid 4D objects which change shape when heated to 45°C. Inspired by natural structures like plants, team of scientists at the Wyss Institute for Biologically Inspired Engineering at Harvard University unveiled 4D-printed hydrogel composite structures that change shape when immersed in water.

Skylar Tibbits, a co-director and founder of the Self-Assembly Lab housed at MIT’s International Design Center, “sees all kinds of future applications for 4D printing. They range from sneakers that change how they fit on your feet based on what activities you are doing to how clothing changes composition based on the weather,” reports All3DP.

It will still take some time before the technology moves past the stage of research and development, and it will take even longer before consumers will be able to walk into a store and buy a 4D printer, but the wide range of examples how the technology could be used in the future shows just how much potential it has to transform fields like manufacturing, logistics, healthcare, and others.